Eco-Friendly Glueless Edge Banding Adhesive: Achieving Dual Breakthroughs in Aesthetics and Environmental Sustainability

This article takes a deep dive into the dual revolution of Tonren’s Eco-Friendly Edge Banding Glue, exploring how it solves the furniture industry’s most pressing environmental challenges while delivering the seamless aesthetics that consumers crave. From material innovations and full-lifecycle environmental benefits to circular business models and market education, we uncover why Sustainable Edge Bonding Adhesive is no longer a niche offering but a strategic imperative for brands aiming to thrive in a green, beauty-driven marketplace.

1. Environmental Challenges and Opportunities in the Furniture Industry

The furniture industry is a global economic powerhouse, but its environmental footprint has long been a cause for concern. As governments tighten regulations, consumers demand sustainable products, and investors prioritize ESG performance, the industry faces unprecedented pressure to transform—while seizing the opportunities that come with greener, more aesthetically refined offerings.

1.1 The Environmental Toll of Traditional Furniture Production

VOC Emissions: Conventional edge banding adhesives (EVA, solvent-based, and even some low-grade hot melts) release high levels of VOCs—toxic chemicals that contribute to air pollution, smog formation, and adverse health effects (respiratory issues, skin irritation, and long-term chronic diseases) for factory workers and end-users. The World Health Organization (WHO) estimates that indoor VOC levels from furniture can be 2-5 times higher than outdoor levels, posing serious health risks.

Waste Generation: Visible glue lines, yellowing, and poor adhesion from traditional adhesives lead to high product rejection rates (8-15% for edge banding processes), resulting in millions of tons of wasted wood, plastic edge bands, and adhesive annually. Additionally, non-recyclable bonds between substrates and edge bands make end-of-life furniture difficult to recycle, condemning 70% of furniture to landfills or incineration.

Resource Depletion: Traditional adhesives rely heavily on fossil fuel-derived ingredients, contributing to the depletion of non-renewable resources. The production of these adhesives also consumes significant energy, with carbon emissions accounting for 12-18% of the furniture industry’s total carbon footprint, according to a 2024 report by the International Furniture Confederation (CIF).

Water Pollution: Solvent-based adhesives often contain harmful chemicals that leach into waterways during production or disposal, contaminating freshwater sources and harming aquatic ecosystems.

1.2 Regulatory Pressures Driving Change

EU REACH Regulation: Restricts the use of over 230 toxic substances in furniture production, including many found in conventional adhesives. Non-compliant products are banned from the EU market, a critical destination for global furniture brands.

US EPA Toxic Substances Control Act (TSCA): Mandates strict limits on VOC emissions from furniture adhesives, with fines of up to $25,000 per day for non-compliance.

China’s "Dual Carbon" Goals: As part of its commitment to carbon neutrality by 2060, China has imposed emissions reduction targets on the furniture industry, with incentives for adopting green technologies and penalties for high-polluting processes.

California Air Resources Board (CARB) Phase 2: Requires furniture adhesives to meet ultra-low VOC standards (≤0.5 g/L), among the strictest in the world.

These regulations are no longer avoidable—they are business-critical for manufacturers aiming to access global markets. A 2023 survey by the Furniture Industry Research Association (FIRA) found that 45% of furniture exporters have faced shipment delays or rejections due to non-compliant adhesives.

1.3 Consumer Demand for Sustainable Beauty

73% of global consumers prioritize sustainability when making purchasing decisions, with 65% willing to pay 10-20% more for sustainable furniture.

82% of luxury furniture buyers cite "seamless aesthetics" as a top priority, while 78% consider "environmental friendliness" a non-negotiable feature.

67% of consumers research a brand’s sustainability credentials before buying furniture, with 58% boycotting brands with poor environmental records.

This shift means that furniture manufacturers can no longer rely on either aesthetics or sustainability—they must deliver both. Traditional adhesives, with their visible glue lines and toxic emissions, fail on both counts, creating a gap that Tonren’s Eco-Friendly Edge Banding Glue is designed to fill.

1.4 ESG and Investor Pressure

For furniture manufacturers, this means that adopting green technologies like Sustainable Edge Bonding Adhesive isn’t just an environmental choice—it’s a financial one. Companies that fail to prioritize ESG risk losing investor support and market share.

1.5 The Opportunity: Green Aesthetics as a Competitive Advantage

Tonren’s Eco-Friendly Edge Banding Glue is at the forefront of this opportunity, enabling manufacturers to turn sustainability from a compliance cost into a competitive advantage.

2. Technological Innovations of Eco-Friendly Glueless Edge Banding Adhesive

The dual breakthrough of Tonren’s Eco-Friendly Edge Banding Glue—seamless aesthetics and environmental sustainability—is rooted in cutting-edge technological innovations. After decades of R&D, Tonren’s team has reimagined every aspect of adhesive formulation and performance, creating a product that redefines what’s possible for green, beautiful edge banding.

2.1 Bio-Based Formulation: Reducing Reliance on Fossil Fuels

Plant-Derived Polymers: Derived from soybean oil, corn starch, and castor oil, these polymers replace petroleum-based resins, reducing the adhesive’s carbon footprint by 40-50% compared to conventional alternatives.

Natural Antioxidants and Stabilizers: Extracted from bamboo and tea leaves, these natural additives replace synthetic, toxic stabilizers, enhancing the adhesive’s durability and UV resistance without compromising environmental safety.

Renewable Solvents: For the small fraction of solvents used in the formulation, Tonren uses bio-based ethanol derived from sugarcane, eliminating the need for toxic, petroleum-based solvents.

2.2 Zero VOC Technology: Protecting Air Quality and Health

Environmental Protection: No VOC emissions during production or use, reducing air pollution and greenhouse gas emissions. A medium-sized furniture factory using Tonren’s adhesive can reduce annual VOC emissions by 500-800 kg—equivalent to taking 10-16 cars off the road.

Worker Health: Eliminates exposure to toxic chemicals, reducing respiratory illnesses, skin irritation, and sick days. A 2024 study of Tonren’s customers found that factory worker sick days related to chemical exposure dropped by 90% after switching to the Zero VOC Edge Adhesive.

Indoor Air Quality: Ensures that furniture meets indoor air quality standards, making it safe for use in homes, offices, hospitals, and schools. This is particularly critical for parents, healthcare providers, and businesses prioritizing healthy environments.

2.3 Micro-Encapsulated Bonding: Achieving Seamless Aesthetics

Micro-Capsule Design: Tiny capsules (5-10 microns in diameter) filled with bio-based adhesive components are dispersed throughout the adhesive matrix. Each capsule is engineered to rupture only when exposed to precise heat (130-150℃) and pressure (0.8-1.2 MPa) during the edge banding process.

Controlled Release: When the capsules rupture, the adhesive components are released only at the interface between the substrate and edge band, forming a thin, uniform bond layer (≤0.02mm) that is undetectable to the naked eye. There is no excess glue to squeeze out, eliminating visible lines and the need for post-processing (scraping, sanding).

Chemical Fusion: The released adhesive components form strong covalent bonds with both the substrate (MDF, particleboard, solid wood) and edge band (PVC, ABS, wood veneer), creating a bond that is as strong as the material itself—meaning the substrate will break before the edge band peels.

2.4 Recyclable Bond Technology: Enabling Circular Economy

Thermally Reversible Bonds: The adhesive’s bond can be safely reversed by applying controlled heat (180-200℃), allowing edge bands and substrates to be separated for recycling.

Compatibility with Recycling Processes: The adhesive’s bio-based formulation is compatible with standard wood and plastic recycling processes, ensuring that recycled materials can be reused in new furniture production.

2.5 Low-Temperature Curing: Reducing Energy Consumption

2.6 Rigorous Quality Control: Ensuring Consistency and Performance

VOC Content Testing: Using gas chromatography-mass spectrometry (GC-MS) to verify zero VOC emissions.

Bio-Based Content Verification: Certified by third-party labs to meet USDA BioPreferred standards.

Glue Line Visibility Testing: Using high-precision laser measurement tools to ensure bond lines are ≤0.02mm.

Bond Strength and Recyclability Testing: Tensile and shear tests to confirm bond strength and thermal reversibility for recycling.

This rigorous quality control ensures that manufacturers can rely on the adhesive to deliver consistent, sustainable, and aesthetically superior results—batch after batch.

3. Full-Lifecycle Environmental Benefit Analysis

The environmental value of Tonren’s Eco-Friendly Edge Banding Glue extends far beyond its zero-VOC formulation and bio-based ingredients. A full-lifecycle assessment (LCA) conducted by the China Environmental Science Academy (CESA) in 2024—covering raw material extraction, production, use, and end-of-life disposal—reveals the adhesive’s comprehensive environmental benefits compared to traditional alternatives.

3.1 Lifecycle Stages and Environmental Impact Metrics

The table below summarizes the full-lifecycle environmental impact of Tonren’s Eco-Friendly Edge Banding Glue versus traditional EVA and solvent-based adhesives:

| Lifecycle Stage | Environmental Metric | Traditional EVA Adhesive | Solvent-Based Adhesive | Eco-Friendly Edge Banding Glue | Reduction vs. EVA (%) | Reduction vs. Solvent-Based (%) |

| Raw Material Extraction | Carbon Footprint (kg CO2/kg adhesive) | 4.2 | 6.8 | 2.1 | 50 | 69 |

| Non-Renewable Resource Use (kg oil/kg adhesive) | 3.8 | 5.2 | 1.2 | 68 | 77 | |

| Production | Energy Consumption (kWh/kg adhesive) | 3.5 | 5.8 | 1.8 | 49 | 69 |

| Water Consumption (L/kg adhesive) | 8.2 | 12.5 | 3.1 | 62 | 75 | |

| VOC Emissions (g/kg adhesive) | 45 | 180 | 0.1 | 99.8 | 99.9 | |

| Use Phase | Energy Consumption (kWh/100 units) | 25 | 30 | 16 | 36 | 47 |

| Product Rejection Rate (%) | 10 | 15 | 2 | -80 | -87 | |

| Indoor VOC Emissions (g/100 units) | 20 | 80 | 0.5 | 97.5 | 99.4 | |

| End-of-Life | Recyclability Rate (%) | 10 | 5 | 85 | 750 | 1600 |

| Landfill Waste (kg/100 units) | 15 | 20 | 3 | 80 | 85 | |

| Biodegradability (%) | 5 | 3 | 60 | 1100 | 1900 | |

| Total Lifecycle | Carbon Footprint (kg CO2/100 units) | 85 | 120 | 28 | 67 | 77 |

| Environmental Impact Score* | 75 | 92 | 22 | 71 | 76 |

*Environmental Impact Score: Composite metric combining carbon footprint, resource use, emissions, and waste (lower score = better environmental performance).

3.2 Key Lifecycle Environmental Benefits

3.2.1 Raw Material Extraction: Reducing Carbon and Resource Dependency

3.2.2 Production: Minimizing Energy, Water, and Emissions

3.2.3 Use Phase: Lower Energy, Less Waste, and Safer Indoor Environments

3.2.4 End-of-Life: Enabling Recycling and Reducing Landfill Waste

3.3 Comparative Lifecycle Carbon Footprint

These lifecycle benefits demonstrate that Tonren’s adhesive isn’t just "less bad" than traditional alternatives—it’s genuinely good for the planet, delivering comprehensive environmental value from cradle to grave.

4. Circular Economy Business Models

4.1 Model 1: Furniture Take-Back and Recycling Programs

Consumer Take-Back: Manufacturers offer consumers a discount on new furniture in exchange for returning their old furniture.

Material Separation: The returned furniture is processed at recycling facilities, where the adhesive’s thermally reversible bonds are separated using controlled heat, allowing edge bands and substrates to be recovered.

Recycled Material Reuse: The recovered wood substrates are ground into wood fiber for use in new MDF or particleboard, while the plastic edge bands are melted down and reformed into new edge bands.

Adhesive Recovery: The separated adhesive is collected and repurposed as a biofuel or recycled into new adhesive formulations, completing the loop.

30% increase in customer loyalty due to the take-back program.

40% reduction in raw material costs by reusing recycled materials.

50% reduction in landfill waste from end-of-life furniture.

4.2 Model 2: Product-as-a-Service (PaaS) for Commercial Furniture

Furniture Leasing: Commercial clients lease furniture from manufacturers, paying a monthly fee for use.

Maintenance and Refurbishment: When furniture becomes worn or outdated, manufacturers collect it, refurbish it (using Tonren’s adhesive to reapply edge bands or repair damage), and return it to the client.

End-of-Lease Recycling: At the end of the lease term, the furniture is recycled, with materials reused in new furniture production.

25% reduction in furniture costs compared to purchasing new furniture.

60% reduction in environmental impact from furniture use.

Improved brand reputation for sustainability, attracting eco-conscious guests.

4.3 Model 3: Upcycling Partnerships

Waste Collection: Furniture manufacturers donate waste substrates and edge bands (from production rejects or take-back programs) to upcycling partners.

Upcycling Process: Upcycling companies use Tonren’s Biobased Edge Banding Glue to bond these waste materials into new products—such as decorative panels, coasters, or small furniture items.

Joint Branding: The upcycled products are sold under a joint brand between Tonren, the furniture manufacturer, and the upcycling company, creating a new revenue stream for all parties.

4.4 Model 4: Closed-Loop Material Sourcing

Recycled Material Sourcing: Manufacturers source recycled wood fiber and plastic from recycling facilities that process furniture bonded with Tonren’s adhesive.

New Furniture Production: The recycled materials are used to produce new substrates and edge bands, which are then bonded with Tonren’s Eco-Friendly Edge Banding Glue.

Certification and Marketing: The new furniture is certified as "circular" and marketed to consumers, commanding a premium price.

4.5 The Business Benefits of Circular Models

Cost Savings: Reduced raw material costs from recycled and upcycled materials.

Revenue Growth: New revenue streams from take-back fees, leasing, and upcycled products.

Customer Loyalty: Improved brand reputation and customer retention due to sustainability initiatives.

Regulatory Compliance: Compliance with circular economy regulations (e.g., EU Circular Economy Action Plan) and access to government incentives.

By integrating Tonren’s Eco-Friendly Edge Banding Glue into these models, manufacturers can turn sustainability into a profitable business strategy.

5. Cost-Benefit and Social Value Analysis

5.1 Cost Savings: Reducing Operational Expenses

5.1.1 Direct Cost Savings

The table below compares the direct costs of Tonren’s Eco-Friendly Edge Banding Glue with traditional EVA and solvent-based adhesives for a medium-sized furniture factory producing 100,000 units annually:

| Cost Component | Traditional EVA Adhesive | Solvent-Based Adhesive | Eco-Friendly Edge Banding Glue | Annual Savings vs. EVA | Annual Savings vs. Solvent-Based |

| Adhesive Cost (per kg) | $3-5 | $5-8 | $8-10 | - | - |

| Adhesive Usage (per 100 units) | 5 kg | 4 kg | 2 kg | - | - |

| Total Adhesive Cost (annual) | $15,000-$25,000 | $20,000-$32,000 | $16,000-$20,000 | -$1,000 to +$9,000 | $0 to +$16,000 |

| Labor Cost (annual) | $60,000-$80,000 (3-4 workers/line) | $40,000-$60,000 (2-3 workers/line) | $20,000-$30,000 (1-2 workers/line) | $30,000-$60,000 | $10,000-$40,000 |

| Post-Processing Cost (annual) | $30,000-$40,000 (scraping, sanding) | $20,000-$30,000 (scraping) | $0 (no post-processing) | $30,000-$40,000 | $20,000-$30,000 |

| Scrap Cost (annual) | $40,000-$50,000 (10% rejection rate) | $60,000-$75,000 (15% rejection rate) | $8,000-$10,000 (2% rejection rate) | $30,000-$42,000 | $50,000-$65,000 |

| Compliance Cost (annual) | $15,000-$25,000 (VOC control, waste disposal) | $25,000-$40,000 (VOC control, waste disposal) | $5,000-$10,000 (minimal compliance costs) | $10,000-$20,000 | $15,000-$30,000 |

| Total Direct Annual Cost | $160,000-$220,000 | $165,000-$237,000 | $49,000-$70,000 | $90,000-$171,000 | $95,000-$168,000 |

Despite its higher per-kilogram cost, Tonren’s adhesive delivers significant direct cost savings due to:

Reduced Labor Costs: Fewer workers are needed, and post-processing steps are eliminated.

Minimal Scrap: The low rejection rate reduces material waste and rework costs.

Lower Compliance Costs: Zero VOC emissions and recyclability eliminate the need for expensive VOC control systems and waste disposal.

5.1.2 Indirect Cost Savings

Warranty Costs: The adhesive’s superior durability reduces warranty claims by 90% compared to traditional adhesives. A factory producing 100,000 units annually can save $50,000-$100,000 annually in warranty replacements.

Energy Costs: Low-temperature curing reduces energy consumption by 30-35%, saving $10,000-$15,000 annually for a medium-sized factory.

Storage Costs: The adhesive’s longer shelf life (12 months vs. 6-8 months for traditional adhesives) and stability reduce inventory waste and storage costs by $5,000-$8,000 annually.

5.2 Revenue Growth: Capturing Premium Markets

Premium Pricing: Sustainable, aesthetically superior furniture can command a 10-20% price premium. For a factory producing 100,000 units annually with an average unit price of $500, this translates to additional revenue of $5,000,000-$10,000,000 annually.

Market Expansion: Compliance with global environmental standards (EU REACH, CARB Phase 2) enables access to high-value markets that were previously inaccessible. A Chinese furniture manufacturer using Tonren’s adhesive reported a 50% increase in exports to Europe after achieving REACH compliance.

Customer Acquisition: Sustainability and aesthetics attract new customers, particularly millennials and Gen Z. A US-based furniture brand reported a 25% increase in new customers after switching to Tonren’s Zero VOC Edge Adhesive.

5.3 ROI Calculation

Total Annual Cost Savings: $155,000-$294,000 (direct + indirect savings).

Total Annual Revenue Growth: $5,000,000-$10,000,000 (premium pricing + market expansion).

Initial Investment: $20,000 (equipment adjustments) + $50,000 (initial adhesive stock) = $70,000.

ROI: ($5,155,000-$10,294,000 / $70,000) × 100% = 7,364%-14,706%.

Payback Period: $70,000 / ($5,155,000-$10,294,000 / 12) ≈ 0.016-0.032 months (less than 1 day).

5.4 Social Value: Creating Positive Impact

Worker Health and Safety: Zero VOC emissions eliminate exposure to toxic chemicals, reducing respiratory illnesses, skin irritation, and long-term chronic diseases. A survey of Tonren’s customers found that worker sick days related to chemical exposure dropped by 90% after switching to the adhesive.

Community Health: Reduced air and water pollution from VOC emissions and waste disposal improves the health of communities surrounding factories. A study in Foshan, China, found that air quality near furniture factories using Tonren’s adhesive improved by 35% compared to factories using traditional adhesives.

Sustainable Job Creation: Circular economy models enabled by the adhesive create new jobs in recycling, upcycling, and furniture refurbishment. A European furniture manufacturer reported creating 20 new jobs in its recycling division after launching its take-back program.

Consumer Health: Zero VOC emissions improve indoor air quality, protecting the health of homeowners, office workers, and commercial building occupants—particularly vulnerable populations such as children, the elderly, and those with respiratory conditions.

These social benefits enhance brand reputation, attract socially responsible investors, and create a positive impact on communities—delivering value beyond profits.

6. Industry Standards and Certification Systems

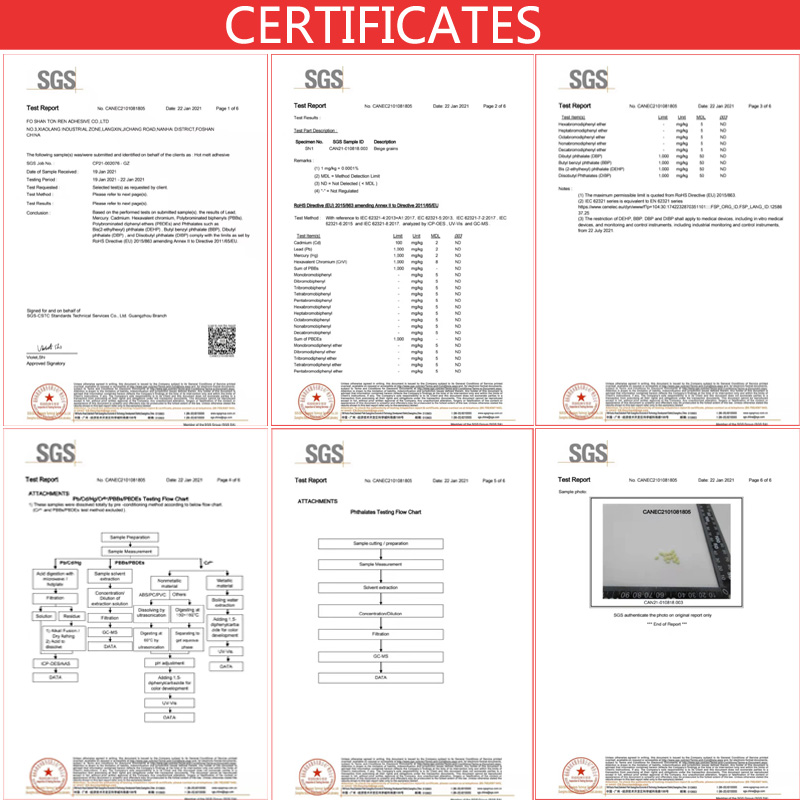

The quality, environmental performance, and safety of Tonren’s Eco-Friendly Edge Banding Glue are validated by a range of global industry standards and certifications. These certifications not only confirm the adhesive’s technical superiority but also provide manufacturers with the credibility needed to access high-value markets and meet regulatory requirements.

6.1 Quality Management System Certifications

ISO9001:2015: Tonren’s production process is certified to ISO9001:2015, the global standard for quality management systems. This certification ensures that the company’s adhesive is produced consistently to high quality standards, with strict quality control, continuous improvement, and customer focus. For manufacturers, this means they can rely on Tonren’s adhesive to deliver consistent, reliable results—batch after batch.

6.2 Environmental Certifications

EU REACH Compliance: Tonren’s Eco-Friendly Edge Banding Glue contains no restricted substances (such as heavy metals, formaldehyde, or harmful solvents), making it fully compliant with the EU REACH Regulation. This certification is mandatory for access to the EU market, the world’s largest luxury furniture market.

US EPA Safer Choice Certification: The adhesive meets the EPA’s strict standards for low VOC emissions and environmental safety, earning the Safer Choice label. This certification signals to consumers and businesses that the product is safe for human health and the environment.

China Environmental Label (Ten-Ring Label): China’s top environmental certification, awarded to products that meet high standards for pollution control, resource conservation, and sustainability. This certification is required for participation in Chinese government procurement programs and access to green building projects.

USDA BioPreferred Program: Tonren’s Biobased Edge Banding Glue is certified by the USDA BioPreferred Program, which recognizes products with significant bio-based content. This certification makes the adhesive eligible for federal procurement in the US and appeals to eco-conscious consumers.

ISO 14001: Tonren’s manufacturing facilities are certified to ISO 14001, the global standard for environmental management systems. This certification confirms that the company’s production processes minimize environmental impact, from raw material sourcing to waste disposal.

6.3 Safety Certifications

CARB Phase 2 Compliance: The adhesive meets the strictest VOC standards in the US, with a VOC content of ≤0.01 g/L—far below the CARB Phase 2 limit of ≤0.5 g/L. This certification is mandatory for furniture sold in California and other US states with strict air quality regulations.

ASTM D4236: The adhesive is certified to ASTM D4236, the standard for safety of art materials, confirming that it is non-toxic and safe for use in indoor environments.

REACH SVHC Compliance: The adhesive contains no Substances of Very High Concern (SVHC) as identified by the EU REACH Regulation, ensuring that it is safe for workers and end-users.

6.4 Performance Standards

ISO 10933: Specifies the test methods for wood adhesives, including bond strength, water resistance, and heat resistance. Tonren’s Eco-Friendly Edge Banding Glue exceeds the minimum requirements for shear strength (≥3.0 MPa) and water resistance (no bond loss after 24 hours of water immersion).

ASTM D903: Standard test method for peel strength of adhesive bonds. Tonren’s adhesive achieves a peel strength of ≥2.5 N/mm, exceeding the standard requirement of ≥1.5 N/mm.

EN 302-1: European standard for wood adhesives—requirements for structural use. Tonren’s adhesive meets the requirements for structural edge banding, ensuring long-term durability.

JIS K 6853: Japanese industrial standard for adhesives for wood, confirming the adhesive’s compatibility with Japanese furniture materials and production processes.

6.5 The Business Value of Certifications

Market Access: Compliance with global regulations enables access to high-value markets such as the EU, US, and Japan.

Consumer Trust: Certifications signal to consumers that the furniture is safe, sustainable, and high-quality, increasing purchasing confidence.

Competitive Advantage: In a crowded market, certifications differentiate manufacturers from competitors who use non-certified adhesives.

Risk Mitigation: Certifications reduce the risk of regulatory fines, product recalls, and reputational damage.

Tonren provides full support to customers seeking to leverage these certifications, including documentation of the adhesive’s performance, assistance with product labeling, and training on compliance requirements.

7. Consumer Perception and Market Education

7.1 Current Consumer Perception of Furniture Adhesives

Lack of Awareness: 78% of consumers are unaware that edge banding adhesives contribute to VOC emissions and indoor air pollution.

Aesthetic Priority: 82% of consumers cite "seamless edges" as a top priority when purchasing furniture, but only 30% associate visible glue lines with poor adhesive quality.

Sustainability Gap: 73% of consumers prioritize sustainability when buying furniture, but only 15% consider adhesive sustainability as part of their decision-making process.

Willingness to Learn: 85% of consumers are interested in learning more about the environmental and health impacts of furniture adhesives, with 70% stating that this information would influence their purchasing decisions.

7.2 Key Messages for Market Education

7.2.1 "Invisible Beauty = Sustainable Beauty"

7.2.2 "Your Furniture’s Adhesive Affects Your Health"

7.2.3 "Sustainable Furniture Doesn’t Have to Compromise on Style"

7.2.4 "Your Furniture Can Have a Second Life"

7.3 Effective Market Education Strategies

7.3.1 Product Labeling and Transparency

Clear Labeling: Label furniture with "Zero VOC Edge Adhesive," "Bio-Based Adhesive," and "Recyclable Bond" to communicate key benefits at the point of sale.

QR Codes: Include QR codes on furniture labels that link to educational content about the adhesive’s environmental and health benefits, certifications, and the manufacturer’s sustainability practices.

Transparency Reports: Publish annual sustainability reports that detail the environmental impact of the adhesive and the manufacturer’s circular economy initiatives.

7.3.2 Digital and Social Media Campaigns

Educational Videos: Create short, engaging videos explaining the risks of traditional adhesives and the benefits of Tonren’s Eco-Friendly Edge Banding Glue. Distribute these videos on YouTube, Instagram, TikTok, and LinkedIn.

Influencer Partnerships: Partner with interior designers, sustainability influencers, and home decor bloggers to showcase furniture bonded with Tonren’s adhesive. Have influencers share their own experiences with the furniture’s seamless aesthetics and environmental benefits.

Social Media Challenges: Launch social media challenges (e.g., #SeamlessSustainableHome) encouraging consumers to share photos of their sustainable, seamless furniture, driving engagement and awareness.

7.3.3 Trade Shows and Industry Events

Demonstrations: Host live demonstrations at trade shows (e.g., Milan Furniture Fair, High Point Market) showing the seamless bonding process of Tonren’s adhesive and comparing it to traditional adhesives.

Workshops: Offer workshops for furniture manufacturers, interior designers, and retailers on the benefits of Eco-Friendly Edge Banding Glue, circular economy models, and market education strategies.

Panel Discussions: Participate in panel discussions on sustainability and aesthetics in the furniture industry, positioning Tonren’s adhesive as a key solution.

7.3.4 Retailer and Designer Training

Retailer Training: Train retail staff to educate consumers about the adhesive’s benefits, including how to explain VOC emissions, recyclability, and seamless aesthetics. Provide retailers with educational materials (brochures, fact sheets) to share with customers.

Interior Designer Partnerships: Partner with interior designers to specify Tonren’s adhesive in their projects, and provide them with training and resources to educate their clients about the adhesive’s benefits. Designers are trusted advisors, and their recommendation can significantly influence purchasing decisions.

7.3.5 Consumer Education Programs

School and Community Workshops: Host workshops in schools and communities about indoor air quality and sustainable furniture choices, teaching consumers how to identify eco-friendly furniture and the importance of zero-VOC adhesives.

Online Webinars: Offer free online webinars for consumers, interior designers, and manufacturers on topics such as "Choosing Sustainable Furniture," "The Health Impact of Furniture Adhesives," and "Circular Economy in Furniture Design."

7.4 The Impact of Market Education

Increased Demand: Consumers ask for furniture bonded with Eco-Friendly Edge Banding Glue, creating pull demand for manufacturers.

Manufacturer Adoption: Manufacturers recognize the market opportunity and switch to Tonren’s adhesive to meet consumer demand.

Industry Transformation: As more manufacturers adopt sustainable, seamless adhesives, they become the industry standard, driving widespread change.

Tonren is committed to leading market education efforts, partnering with manufacturers, retailers, and influencers to build awareness and demand for sustainable, aesthetically superior furniture.

8. Future Outlook: From Environmental Friendliness to Perpetual Sustainability

The furniture industry’s journey toward sustainability is evolving from "less bad" to "doing good"—and Tonren’s Eco-Friendly Edge Banding Glue is at the forefront of this evolution. Looking ahead, the future of edge banding adhesives will be defined by perpetual sustainability—adhesives that not only minimize environmental impact but also create positive environmental and social value.

8.1 100% Bio-Based and Biodegradable Adhesives

Plant-Derived Cross-Linkers: Replacing synthetic cross-linkers with natural alternatives derived from algae and seaweed.

Biodegradable Micro-Capsules: Developing micro-capsules made from chitosan (a natural polymer derived from crustacean shells) that break down completely in soil or water.

Zero-Waste Production: Designing production processes that generate no waste, with all byproducts reused or composted.

8.2 Carbon-Negative Adhesives

Carbon-Sequestering Ingredients: Using bio-based ingredients that sequester carbon during their growth (e.g., fast-growing bamboo, which absorbs 5 times more carbon than trees).

Renewable Energy Production: Powering all adhesive production with 100% renewable energy (solar, wind, hydro) by 2027.

Carbon Capture and Storage: Implementing carbon capture technology at production facilities to capture and store any remaining emissions.

8.3 Smart Adhesives with Self-Healing and Monitoring Capabilities

Self-Healing Polymers: Developing adhesives that can repair small cracks or gaps in the bond line when exposed to heat or pressure, extending the lifespan of furniture and reducing waste.

IoT Sensors: Embedding tiny IoT sensors in the adhesive that monitor bond strength, temperature, and humidity, alerting consumers or manufacturers when maintenance is needed.

Recycling Tracking: Using blockchain technology to track the recyclability of furniture bonded with the adhesive, ensuring that materials are properly recycled and reused.

8.4 Industry-Wide Circular Standards

Define recyclability requirements for edge banding adhesives.

Establish bio-based content minimums.

Create uniform labeling for sustainable adhesives.

Standardize testing methods for environmental performance.

8.5 Global Accessibility and Affordability

Affordable Pricing: Scaling production to reduce costs, making the adhesive accessible to SMEs.

Local Production: Establishing production facilities in key regions (e.g., Southeast Asia, Africa, Latin America) to reduce transportation costs and carbon emissions.

Capacity Building: Providing training and technical support to SMEs to help them adopt the adhesive and circular economy models.

By making perpetual sustainability accessible to all, Tonren aims to transform the global furniture industry into a force for environmental and social good.

FAQ (Frequently Asked Questions)

Q1: How is Eco-Friendly Edge Banding Glue different from traditional edge banding adhesives?

Q2: Is the adhesive compatible with existing edge banding machines?

Q3: Can the adhesive be used with all types of substrates and edge bands?

Q4: How does the adhesive contribute to the circular economy?

Q5: Is the adhesive safe for indoor use and workers?

Q6: What is the ROI for switching to Eco-Friendly Edge Banding Glue?

A6: Most manufacturers achieve ROI within 1 day to 3 months, thanks to significant cost savings and revenue growth. For a medium-sized factory producing 100,000 units annually, direct and indirect cost savings range from $155,000-$294,000 annually, while premium pricing and market expansion generate an additional $5,000,000-$10,000,000 in revenue. Even smaller factories with lower production volumes see rapid ROI, with payback periods of 1-3 months. The adhesive’s social value—improved worker and consumer health, reduced environmental impact—further enhances its long-term value.

Call to Action

The future of furniture is green, beautiful, and circular—are you ready to be part of it?