Revolutionary Recyclable Profile Wrapping Adhesive Launches — Foshan Tonren Adhesive Leads the Way in Circular Economy Innovation

Breaking the Recycling Barrier in Composite Materials

Under the global wave of carbon neutrality and green manufacturing, the recycling of composite materials has become one of the hardest challenges in industrial sustainability.

From building facades to EV interiors, from high-speed train panels to consumer electronics, composites are everywhere — lightweight, strong, and stylish. Yet their inseparable nature makes them nearly impossible to recycle once bonded.

Now, this long-standing bottleneck is being solved by a breakthrough from China’s Foshan Tonren Adhesive Co., Ltd.

After years of R&D and material science innovation, Tonren proudly launches the world-leading Recyclable Profile Wrapping Adhesive and Debondable Profile Wrapping Adhesive — revolutionary products that redefine how materials bond, separate, and return to the circular economy.

1. The Hidden Pollution: When Strong Bonds Block Recycling

In traditional industries, composites such as aluminum-plastic panels, PVC surfaces, ABS supports, and PU foam interiors have built the backbone of modern life — but also created an invisible recycling crisis.

When products reach end-of-life, these materials are typically crushed or incinerated. Metals and plastics cannot be separated due to permanent adhesive bonding, making recycling nearly impossible.

Strong structural adhesives, especially those used in construction and transportation, lock materials together for good.

According to estimates, over 80 million tons of composite waste worldwide cannot be recycled each year due to adhesive bonding.

As one circular economy expert put it:

“Adhesives are both the foundation and the barrier of recycling. Their strength gives products stability — but also traps resources permanently.”

2. From ‘Stick Forever’ to ‘Separate Smartly’: A Green Revolution in Bonding

In the global composite industry, the irony is clear — the better the glue, the worse the recycling.

For decades, engineers have pursued stronger, more durable adhesives: from PUR Hotmelt Profile Wrapping Adhesive to PU Profile Wrapping Adhesive, improving performance in facades, EV interiors, and decorative panels. But when products reach end-of-life, these perfect bonds become a recycler’s nightmare.

That’s where Tonren’s scientists made a bold decision:

“Let it bond firmly when needed — and separate gracefully when it’s time.”

After three years of relentless development, Tonren introduced a game-changing solution:

the Recyclable Profile Wrapping Adhesive and Debondable Profile Wrapping Adhesive series.

These adhesives behave like traditional EVA Hotmelt Profile Wrapping Adhesive in normal use — high strength, weather resistance, durability — but during recycling, a specific trigger such as heat, light, or solvent causes the molecular chain to “let go,” allowing each layer of metal, plastic, or composite to separate cleanly.

It’s like a “controlled relationship” —

solid and protective when together, gentle and residue-free when apart.

Tonren’s engineers humorously describe it as:

“A smart adhesive that knows when to hold tight, and when to let go.”

This marks a fundamental shift — from permanent bonding to reversible connection, opening the door to a truly green manufacturing era.

3. Smart Bonding Technology — Intelligent Connections for a Sustainable Future

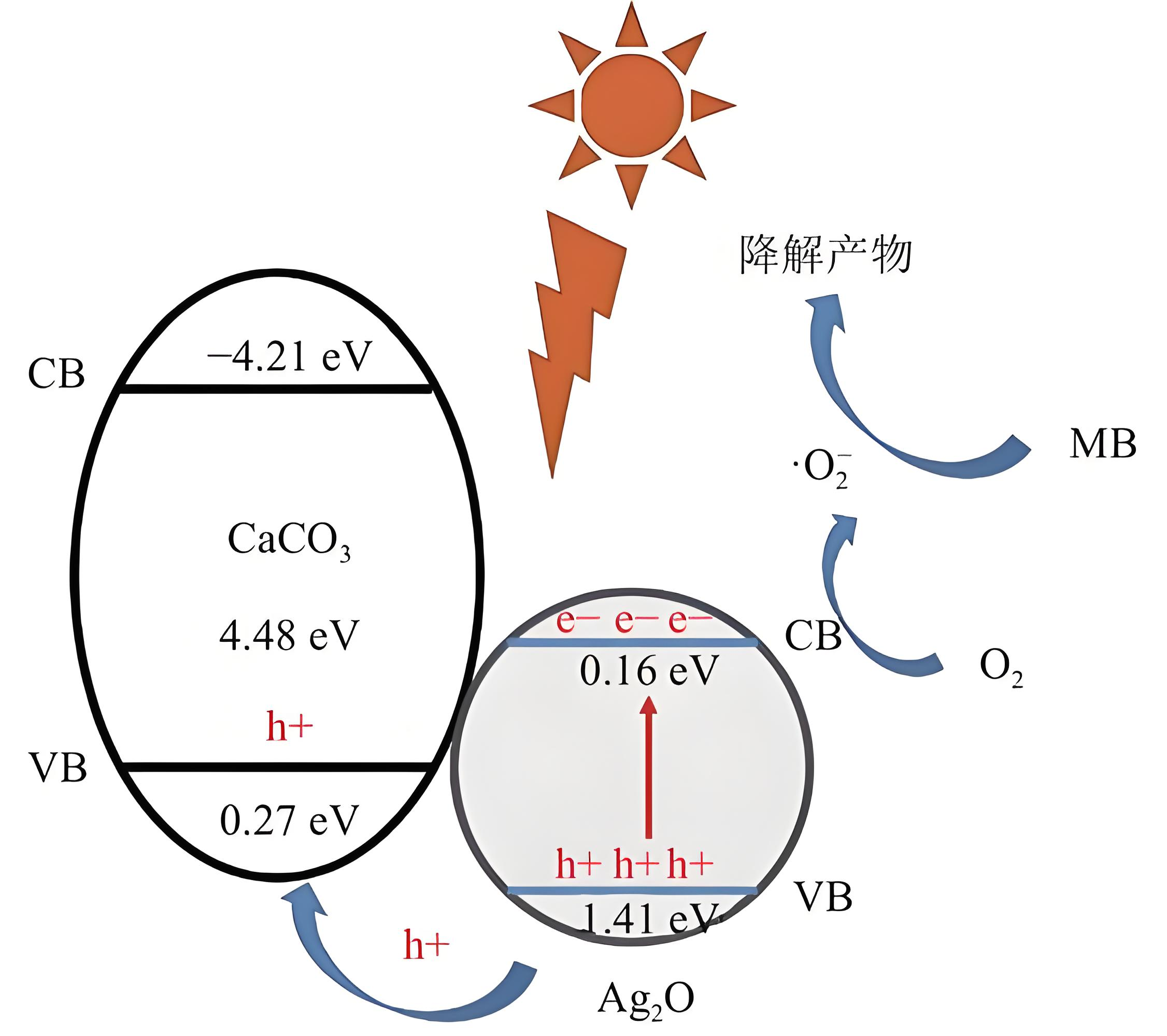

Tonren’s breakthrough is powered by what the company calls Smart Bonding Technology, based on a controlled debonding reaction mechanism.

By engineering special molecular chains, the PU Profile Wrapping Adhesive can break and deactivate its bonds when exposed to specific thermal or solvent conditions.

Unlike traditional adhesives, this technology turns bonding from a one-way decision into a reversible strategy — ensuring both strong adhesion during use and easy disassembly during recycling.

Tonren’s engineers describe it vividly as:

“A controllable chemical handshake — unbreakable when needed, graceful when released.”

4. Multi-Dimensional Advantages: Eco-Friendly Performance Without Compromise

In the sustainable materials world, people often assume that “green” means “weaker” or “more expensive.” Tonren is proving otherwise.

♻ Closed-Loop Recycling — Giving Materials a Second Life

In the past, composites were like irreversible marriages — once bonded, forever inseparable.

Now, with Tonren’s on-demand debonding technology, the aluminum-plastic separation rate reaches 98%, enabling materials to re-enter production cycles while cutting incineration energy and carbon emissions.

In European pilot projects, using PU Profile Wrapping Adhesive reduced overall recycling costs by up to 40%.

💪 Performance That Doesn’t Break a Sweat

“Recyclable” doesn’t mean “fragile.”

Tests show Tonren’s adhesives maintain high bonding strength under 70°C heat, -30°C cold, and 95% humidity, matching the performance of conventional PUR Hotmelt Profile Wrapping Adhesive.

Its flexibility and vibration resistance are even better — ideal for EV interiors, rail systems, and architectural composites.

✅ Regulation-Friendly, Globally Certified

As EU Green Deal and ESG regulations tighten, compliance is key.

Tonren’s EVA Hotmelt Profile Wrapping Adhesive series has passed RoHS, REACH, and UL certifications, offering customers a fast track to global market access and sustainable branding advantage.

🎨 Design Freedom, Unlocked

Traditional structural adhesives often force designers to compromise between strength and removability.

Tonren’s new recyclable adhesives free them from this tradeoff — enabling bold, streamlined designs for EV dashboards, high-end furniture, and modular interiors that can be perfectly assembled and easily detached.

As Tonren’s R&D Director puts it:

“Our adhesive doesn’t make the world stickier — it makes it easier to rebuild.”

In this material revolution, Tonren is not just offering a product — it’s offering a new way of thinking: sustainability as innovation, not compromise.

5. Industry Impact: A Catalyst for the Circular Economy

Experts from the China Circular Economy Association describe Tonren’s innovation as

“A breakthrough that turns composite materials from unrecyclable waste into circular resources — a true disruptor for global green manufacturing.”

A European automotive interior supplier found that switching to Tonren’s PU Profile Wrapping Adhesive reduced recycling energy use by 40% and increased material reuse by 60% — proof that sustainability and profitability can coexist.

With this success, Tonren is paving the way for an entirely new “deconstructable era” across automotive, architecture, and furniture industries.

6. Tonren’s Commitment: From Stability to Sustainable Innovation

Founded in 1999, Foshan Tonren Adhesive has built its reputation on two pillars — consistency and innovation.

With 26+ years of adhesive R&D and a 25% R&D team ratio, the company is certified under ISO 9001 and operates nationwide offices in Changsha, Zhengzhou, Yongkang, and Chengdu for full after-sales support.

This long-term commitment to quality and progress has allowed Tonren to lead globally with its Recyclable and Debondable Profile Wrapping Adhesives — reshaping the adhesive industry’s role in sustainable development.

7. Looking Ahead: Making the World Easier to Unbond

Tonren plans to expand its debondable technology into multiple high-tech sectors:

EV manufacturing: detachable bonding for automotive panels and interiors

Green architecture: replace permanent structural adhesives in facade systems

Consumer electronics: recyclable design for smartphones and laptops

Rail transportation: low-energy interior disassembly

Tonren’s mission is clear:

“To make every drop of adhesive not only hold things together — but also let them go gracefully when needed.”

That’s the essence of truly sustainable bonding technology.

FAQ

Q1: What’s the key difference between Recyclable Profile Wrapping Adhesive and traditional hotmelt glue?

Traditional adhesives like PUR Hotmelt are irreversible once cured. Tonren’s new products can deactivate under specific conditions, enabling material recovery and reuse.

Q2: Does the Debondable Adhesive sacrifice bonding strength?

No. Tests show comparable or superior bonding strength to PU Profile Wrapping Adhesive, even under humid environments.

Q3: Is it compliant with global environmental regulations?

Absolutely. All Tonren adhesive series, including EVA Hotmelt, meet EU RoHS, REACH, and UL standards.

Q4: Can it be used on existing production lines?

Yes. It’s highly compatible with current PUR Hotmelt equipment — no major upgrades required.

Q5: Are biodegradable versions planned?

Yes. Tonren is developing next-generation bio-based and biodegradable PU adhesives, continuing to lead in green innovation.

Conclusion

In the global movement toward green transformation, every breakthrough matters.

With deep expertise and a bold vision, Foshan Tonren Adhesive Co., Ltd. has turned what was once the greatest obstacle of recycling — adhesives — into a new driving force of the circular economy.

Tonren Adhesive: Greener Connections. Recyclable Futures.