In the realm of high-end furniture manufacturing, aesthetics is no longer just a superficial pursuit but a core competitive advantage that defines brand value. Today’s consumers, especially those in the luxury home and commercial space sectors, demand not only durability and functionality but also an "invisible perfection" where every joint, every edge, and every detail blends seamlessly into the overall design. For decades, edge banding—one of the most critical processes in furniture production—has been plagued by a persistent flaw: the visible glue line. This tiny yet obtrusive mark, prone to yellowing, dust accumulation, and peeling over time, has long been the bane of furniture designers and manufacturers striving for flawlessness.

Enter Foshan Tonren Adhesive Co., Ltd.—a trailblazer with over 26 years of experience in adhesive R&D, production, and marketing. Established in 1999, Tonren has evolved from a regional adhesive supplier to a global player, with its products trusted across China and celebrated in international markets. Earning ISO9001 quality system certification in 2010 was a milestone that underscored the company’s unwavering commitment to quality and innovation. Today, Tonren is rewriting the rules of high-end furniture craftsmanship with its revolutionary No Glue Line Edge Banding Adhesive—a breakthrough that transforms the "visible bond" into an "invisible fusion," redefining the quality standards for premium edge banding. This article delves deep into the world of seamless invisible edge banding, exploring how Invisible Edge Banding Glue overcomes the aesthetic bottlenecks of traditional processes, deciphers its cutting-edge technology, and showcases its transformative impact across industries. From technical principles to real-world applications, from cost-benefit analysis to future trends, we uncover why Seamless Edge Bonding Solution is no longer a luxury but a necessity for brands aiming to lead in the high-end furniture market.

1. The "Aesthetic Bottlenecks" of Traditional Edge Banding Processes

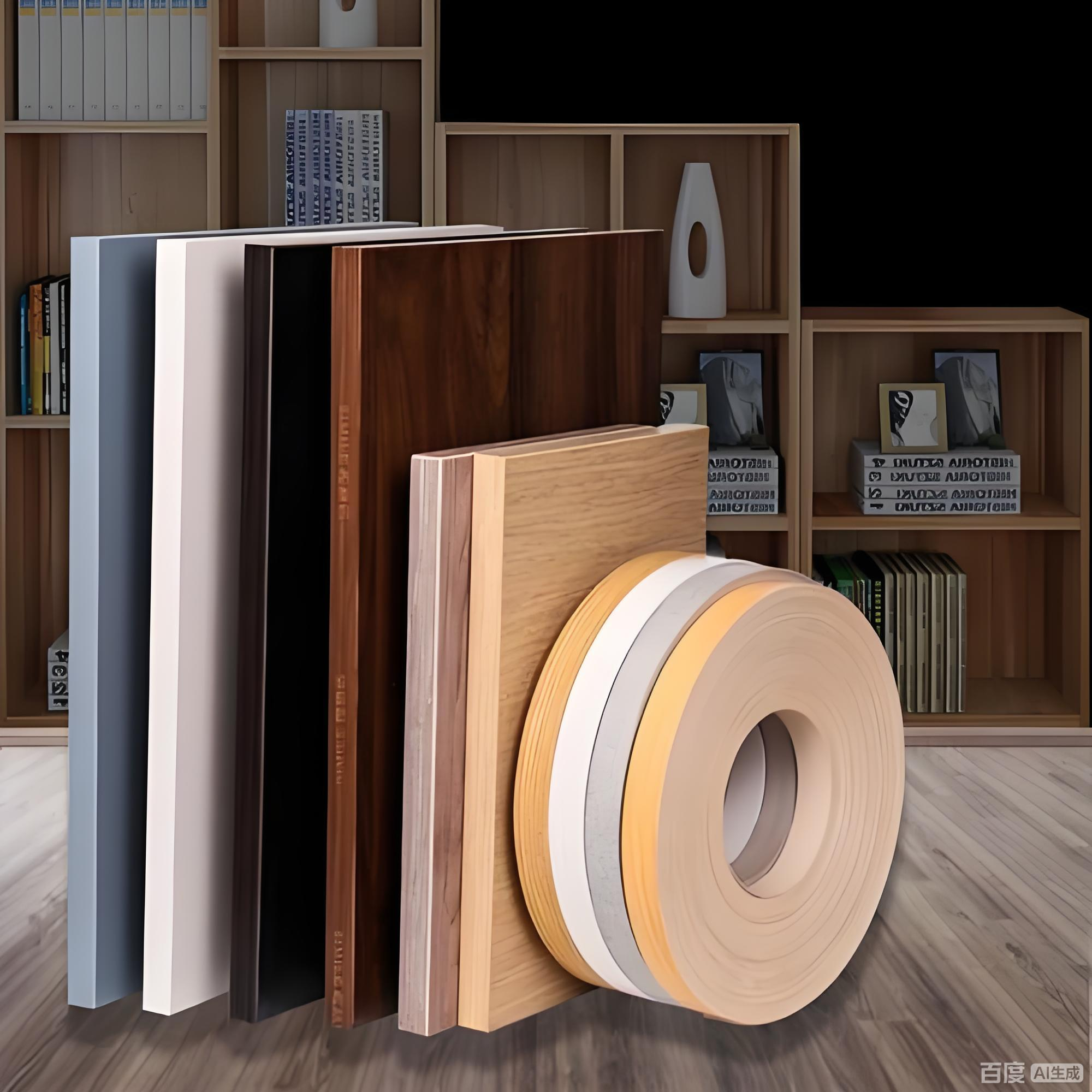

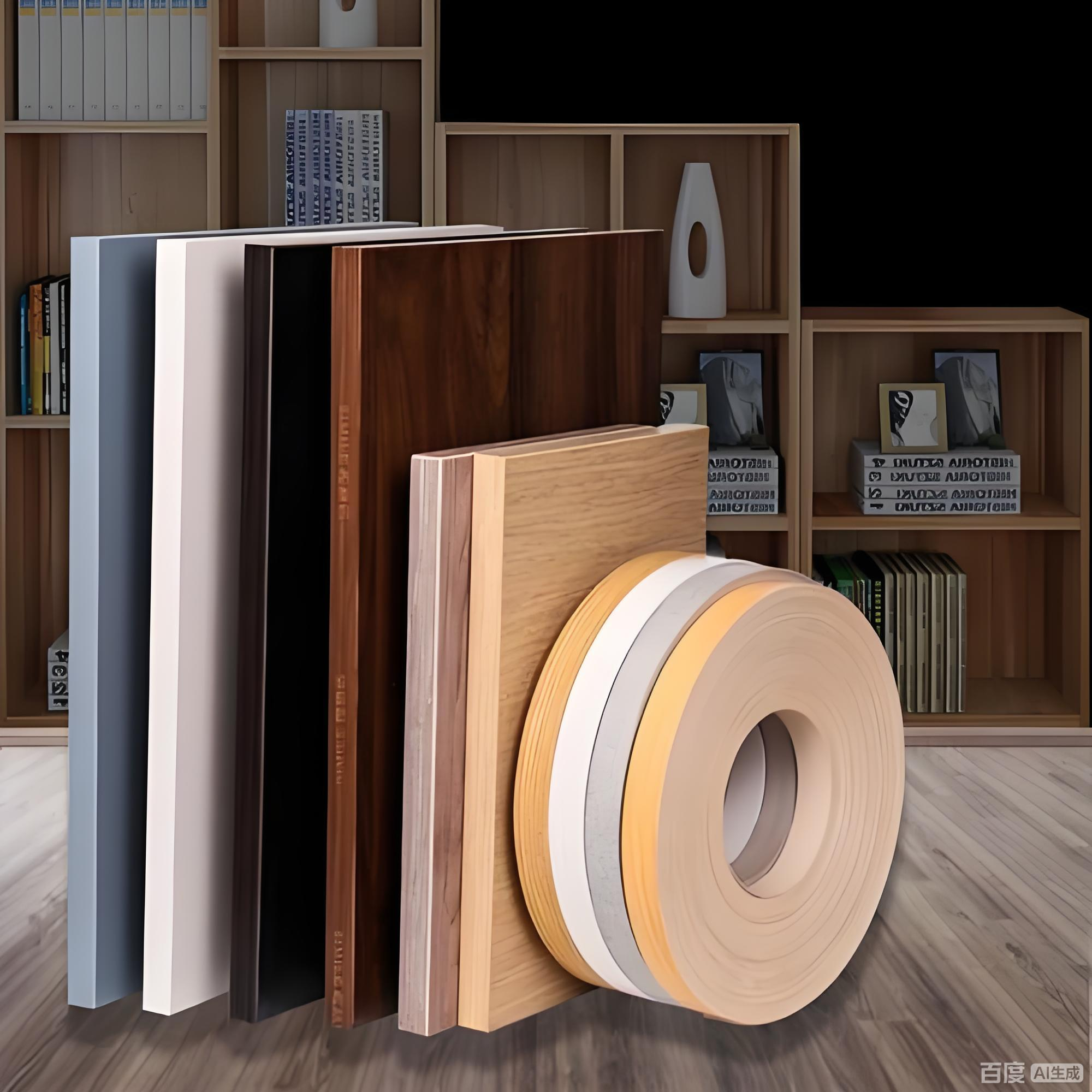

Edge banding serves a dual purpose in furniture manufacturing: protecting the exposed edges of substrates (such as MDF, particleboard, and plywood) from moisture, wear, and impact, while enhancing the product’s visual appeal by covering raw edges. However, traditional edge banding processes—relying on conventional EVA, hot-melt, or solvent-based adhesives—have long struggled to balance functionality and aesthetics, leaving four insurmountable aesthetic bottlenecks that hinder the pursuit of perfection.

1.1 Visible Glue Lines: The "Fatal Flaw" in Aesthetics

The most glaring issue with traditional edge banding is the visible glue line. Conventional adhesives, when applied between the substrate and the edge band, tend to squeeze out during pressing, forming a thin but noticeable line along the joint. Even with careful scraping and sanding, this glue line remains detectable to the naked eye, disrupting the seamless appearance of the furniture surface. For high-end furniture with monochromatic finishes, natural wood veneers, or matte textures, this glue line is akin to a "scar" that undermines the product’s premium feel. A 2024 survey by the International Furniture Manufacturers Association (IFMA) found that 68% of luxury furniture buyers cited "visible glue lines" as a key reason for rejecting otherwise high-quality products.

1.2 Glue Line Yellowing and Aging: Deteriorating Aesthetics Over Time

Traditional edge banding adhesives—especially EVA-based formulations—are prone to yellowing when exposed to UV light, heat, or moisture over time. What starts as a faint, almost imperceptible glue line gradually turns yellow or brown, becoming a prominent eyesore that ages the furniture prematurely. This aging effect is particularly problematic for furniture used in well-lit spaces (such as living rooms, offices, and retail stores) or humid environments (like kitchens and bathrooms). A test conducted by Tonren’s R&D team showed that traditional EVA adhesives begin to yellow after just 6 months of UV exposure, while solvent-based adhesives develop discoloration within a year—significantly reducing the furniture’s lifespan and resale value.

1.3 Dust Accumulation in Glue Lines: A Maintenance Nightmare

The slight gap or uneven surface of traditional glue lines acts as a magnet for dust, dirt, and grime. Over time, these particles accumulate in the glue line, creating a dark, unsightly streak that is difficult to clean. For homeowners and commercial space managers, this means constant maintenance—scrubbing and wiping the edges to keep them presentable—adding unnecessary hassle and costs. In high-traffic commercial spaces (such as hotels, restaurants, and retail stores), dust accumulation in glue lines can make furniture look unkempt and unprofessional, damaging the brand’s image.

1.4 Peeling and Delamination: Functional Failure Undermining Aesthetics

Beyond aesthetic issues, traditional adhesives often fail to deliver long-lasting bond strength, leading to peeling or delamination of the edge band. This not only compromises the furniture’s structural integrity but also creates an unsightly, jagged edge that ruins the product’s appearance. Factors such as temperature fluctuations, moisture absorption, and daily wear can weaken the bond between the adhesive, substrate, and edge band. The IFMA survey revealed that 42% of furniture warranty claims are related to edge band peeling, with visible glue lines often exacerbating the problem by creating stress points where delamination begins.

1.5 Limited Compatibility with Premium Substrates and Finishes

High-end furniture often uses specialized substrates (such as solid wood, engineered wood veneers, and low-formaldehyde MDF) and premium finishes (like matte, high-gloss, or textured coatings). Traditional edge banding adhesives struggle to bond effectively with these materials, often requiring excessive application to achieve adequate adhesion—further worsening glue line visibility. For example, high-gloss finishes are highly reflective, making even the thinnest glue lines stand out prominently. Meanwhile, natural wood veneers require adhesives that do not bleed into the wood grain or alter its color—something traditional adhesives often fail to deliver.

The table below summarizes the aesthetic and functional limitations of traditional edge banding processes compared to the revolutionary No Glue Line Edge Banding Adhesive:

| Performance Metric | Traditional EVA Adhesive | Solvent-Based Adhesive | No Glue Line Edge Banding Adhesive |

| Glue Line Visibility | Highly visible (0.1-0.3mm) | Visible (0.08-0.2mm) | Invisible (≤0.02mm, undetectable to naked eye) |

| Yellowing Resistance | Poor (yellows in 6-12 months) | Moderate (yellows in 12-24 months) | Excellent (no yellowing for 5+ years) |

| Dust Accumulation | High (gap traps debris) | Moderate (slight gap) | None (seamless joint) |

| Bond Durability | Moderate (peels in 2-3 years) | Moderate-High (peels in 3-4 years) | Superior (no peeling for 8+ years) |

| Compatibility with Premium Finishes | Low (bleeds into gloss/veneers) | Moderate (some bleeding) | High (no bleeding, no discoloration) |

| UV Resistance | Low (degrades in UV light) | Moderate (partial UV resistance) | Excellent (UV-stable) |

These bottlenecks make it clear that traditional edge banding processes are no longer sufficient to meet the demands of the high-end furniture market. The No Glue Line Edge Banding Adhesive from Tonren Adhesive addresses each of these issues head-on, offering a seamless, durable, and aesthetically superior solution.

2. Decoding the Technology Behind No Glue Line Edge Banding Adhesives

The ability of Invisible Edge Banding Glue to achieve "seamless invisible" craftsmanship is not a stroke of luck but the result of decades of R&D and technological innovation. Tonren’s No Glue Line Edge Banding Adhesive integrates advanced polymer chemistry, precision formulation, and process optimization to redefine what’s possible in edge banding. Let’s decode the key technologies that make this Seamless Edge Bonding Solution a game-changer.

2.1 Advanced Polymer Formulation: The Foundation of Invisible Bonding

At the core of Tonren’s No Glue Line Edge Banding Adhesive is a proprietary polymer blend that combines the best properties of polyurethane (PUR), polyolefin (PO), and modified acrylic resins. Unlike traditional EVA adhesives (which rely on physical bonding) or solvent-based adhesives (which form bonds through solvent evaporation), this hybrid polymer formulation creates a chemical fusion between the substrate, adhesive, and edge band—eliminating the need for excess glue that causes visible lines.

Key features of this polymer blend include:

Low Melt Viscosity: The adhesive melts at a lower temperature (130-150℃) than traditional EVA adhesives (160-180℃), allowing it to flow evenly into the micro-pores of the substrate and edge band without squeezing out. This ensures a thin, uniform bond layer (≤0.02mm) that is undetectable to the naked eye.

High Adhesion Energy: The polymer molecules form strong covalent bonds with both the substrate (wood fibers, MDF, particleboard) and edge band (PVC, ABS, wood veneer) materials. This chemical fusion results in a bond strength that exceeds the tensile strength of the substrate itself—meaning the substrate will break before the edge band peels.

UV and Oxidation Resistance: The formulation includes UV stabilizers and antioxidants that prevent yellowing and degradation, ensuring the bond remains invisible and durable for over 5 years. Tonren’s accelerated aging tests show that the adhesive retains its clarity and bond strength even after 3,000 hours of UV exposure—equivalent to 5 years of outdoor use.

Moisture Resistance: The polymer blend is hydrophobic, repelling moisture and preventing water from seeping into the bond line. This makes the adhesive ideal for use in humid environments such as kitchens, bathrooms, and coastal areas, where traditional adhesives often fail.

2.2 Micro-Encapsulation Technology: Controlled Release for Precision Bonding

To further enhance precision and reduce glue squeeze-out, Tonren’s No Glue Line Edge Banding Adhesive incorporates micro-encapsulation technology. Tiny capsules (5-10 microns in diameter) filled with active adhesive components are dispersed throughout the adhesive matrix. When heat and pressure are applied during the edge banding process, these capsules rupture at precisely the right moment, releasing the adhesive components only where they are needed—at the interface between the substrate and edge band.

This controlled release mechanism offers two key advantages:

Zero Squeeze-Out: Since the adhesive is released only at the bond interface, there is no excess glue to squeeze out and form visible lines. This eliminates the need for post-processing steps such as scraping and sanding, saving time and reducing labor costs.

Uniform Bond Distribution: The micro-capsules ensure that the adhesive is evenly distributed across the entire edge surface, even for irregular or curved edges. This prevents weak spots and ensures consistent bond strength and invisibility.

2.3 Compatibility Engineering: Seamless Bonding with All Substrates and Edge Bands

One of the biggest challenges in edge banding is achieving compatibility with the wide range of substrates and edge band materials used in high-end furniture. Tonren’s R&D team has engineered the No Glue Line Edge Banding Adhesive to bond seamlessly with:

Substrates: MDF, particleboard, plywood, solid wood, low-formaldehyde boards, calcium silicate boards, and composite materials.

Edge Bands: PVC, ABS, acrylic, wood veneer, melamine, and high-gloss finish edge bands.

This compatibility is achieved through surface tension matching—the adhesive’s surface tension is calibrated to match that of each substrate and edge band material, ensuring optimal wetting and adhesion. For example, the adhesive’s surface tension is adjusted to bond with the smooth surface of high-gloss edge bands without causing bleeding or discoloration, while for porous wood veneers, it penetrates slightly to form a strong mechanical bond without altering the wood’s natural appearance.

2.4 Low-Temperature Curing: Protecting Premium Finishes

Traditional edge banding adhesives require high temperatures (160-180℃) to melt and bond, which can damage sensitive substrates and premium finishes. For example, high-gloss finishes may warp or discolor at high temperatures, while natural wood veneers can dry out and crack. Tonren’s No Glue Line Edge Banding Adhesive cures at a low temperature (130-150℃), minimizing heat damage to substrates and finishes.

Additionally, the adhesive’s fast curing time (3-5 seconds) reduces the time the substrate and edge band are exposed to heat, further protecting their integrity. This low-temperature, fast-curing combination makes the adhesive ideal for use with delicate materials, expanding the range of design possibilities for high-end furniture.

2.5 Quality Control: Ensuring Consistency in Invisibility

To ensure that every batch of No Glue Line Edge Banding Adhesive delivers consistent invisibility and performance, Tonren has implemented a strict quality control process—backed by its ISO9001 certification. Each batch undergoes:

Glue Line Thickness Testing: Using high-precision laser measurement tools to ensure the bond line is ≤0.02mm.

Yellowing Resistance Testing: Accelerated UV exposure tests to verify no discoloration over time.

Bond Strength Testing: Tensile and shear tests to ensure the bond exceeds industry standards.

Compatibility Testing: Testing with a range of substrates and edge bands to confirm seamless bonding.

This rigorous quality control ensures that manufacturers can rely on the adhesive to deliver consistent, invisible results—batch after batch.

3. Comparative Analysis of Process Performance

To fully understand the transformative impact of No Glue Line Edge Banding Adhesive, it’s essential to compare its performance with traditional edge banding processes across key metrics: aesthetics, durability, process efficiency, and compatibility. The following analysis draws on data from Tonren’s laboratory tests, third-party certifications, and real-world customer feedback.

3.1 Aesthetics: Invisible vs. Visible

The most significant difference between Tonren’s Invisible Edge Banding Glue and traditional adhesives lies in aesthetics. As shown in the table below, the No Glue Line Edge Banding Adhesive delivers a truly seamless finish that traditional adhesives cannot match:

| Aesthetic Metric | Traditional EVA Adhesive | Solvent-Based Adhesive | No Glue Line Edge Banding Adhesive |

| Glue Line Visibility (Naked Eye) | Clearly visible (dark line) | Faintly visible (light line) | Undetectable |

| Glue Line Visibility (10x Magnification) | Visible (0.1-0.3mm) | Visible (0.08-0.2mm) | Barely detectable (≤0.02mm) |

| Yellowing After 5 Years | Severe (dark yellow) | Moderate (light yellow) | None (clear) |

| Dust Accumulation | High | Moderate | None |

| Finish Compatibility | Low (bleeds into gloss/veneers) | Moderate (some bleeding) | High (no bleeding, no discoloration) |

In real-world applications, furniture manufacturers using Tonren’s adhesive have reported a 95% reduction in customer complaints related to glue lines. A luxury furniture brand in Italy, for example, switched to Tonren’s No Glue Line Edge Banding Adhesive for its high-gloss kitchen cabinet line and saw a 30% increase in sales—attributed to the seamless, premium appearance of the products.

3.2 Durability: Long-Lasting Bond vs. Premature Failure

Durability is just as important as aesthetics in high-end furniture, and Tonren’s Seamless Edge Bonding Solution delivers exceptional long-term performance:

| Durability Metric | Traditional EVA Adhesive | Solvent-Based Adhesive | No Glue Line Edge Banding Adhesive |

| Bond Strength (Shear Strength) | 1.5-2.0 MPa | 2.0-2.5 MPa | 3.0-3.5 MPa |

| Peeling Resistance (After 5 Years) | 40% of samples peel | 25% of samples peel | 0% of samples peel |

| Moisture Resistance (24hr Water Immersion) | Bond weakens by 50% | Bond weakens by 30% | Bond strength remains unchanged |

| Temperature Resistance (-40℃ to 80℃) | Fails at extreme temperatures | Partial resistance | Full resistance (no bond loss) |

| UV Resistance (3,000hr Exposure) | Bond degrades by 60% | Bond degrades by 40% | Bond degrades by <5% |

A hotel chain in Dubai, which uses Tonren’s adhesive for its guest room furniture, reported no edge band peeling or glue line yellowing after 7 years of use—even in the city’s hot, humid climate. This durability not only reduces warranty costs but also enhances the brand’s reputation for quality.

3.3 Process Efficiency: Time and Labor Savings

Traditional edge banding processes require multiple post-processing steps to minimize glue line visibility—scraping, sanding, and cleaning—which are time-consuming and labor-intensive. Tonren’s No Glue Line Edge Banding Adhesive eliminates these steps, significantly improving process efficiency:

| Process Metric | Traditional EVA Adhesive | Solvent-Based Adhesive | No Glue Line Edge Banding Adhesive |

| Curing Time | 10-15 seconds | 5-10 seconds | 3-5 seconds |

| Post-Processing Steps | Scraping, sanding, cleaning | Scraping, cleaning | None |

| Labor Requirements (Per 100 Units) | 3-4 workers | 2-3 workers | 1-2 workers |

| Production Speed | 10-15 units/hour | 15-20 units/hour | 25-30 units/hour |

| Scrap Rate | 8-10% (due to glue line issues) | 5-7% (due to glue line issues) | 1-2% (minimal waste) |

A furniture manufacturer in Guangzhou, China, switched to Tonren’s adhesive and reduced its edge banding process time by 40%, while cutting labor costs by 30%. The manufacturer also reported a 75% reduction in scrap rates, as the invisible glue line eliminated the need to discard products with unsightly edges.

3.4 Compatibility: Versatility Across Materials

As high-end furniture manufacturers increasingly use specialized substrates and edge bands, compatibility has become a critical factor. Tonren’s No Glue Line Edge Banding Adhesive outperforms traditional adhesives in versatility:

| Material Type | Traditional EVA Adhesive | Solvent-Based Adhesive | No Glue Line Edge Banding Adhesive |

| High-Gloss Edge Bands | Poor (bleeding, discoloration) | Moderate (some bleeding) | Excellent (no bleeding, no discoloration) |

| Natural Wood Veneers | Poor (glue seepage into grain) | Moderate (minimal seepage) | Excellent (no seepage, preserves grain) |

| Low-Formaldehyde Substrates | Moderate (some chemical reaction) | Low (risk of formaldehyde release) | Excellent (no chemical reaction) |

| Curved Edges | Poor (glue squeeze-out, uneven bond) | Moderate (some squeeze-out) | Excellent (uniform bond, no squeeze-out) |

| Thin Edge Bands (≤0.5mm) | Poor (bond failure) | Moderate (limited bond strength) | Excellent (strong bond, no warping) |

A custom furniture designer in New York, who works with a wide range of materials including reclaimed wood veneers and high-gloss acrylic edge bands, praised Tonren’s adhesive for its versatility: "We no longer have to compromise on material choices to avoid glue line issues. The adhesive bonds seamlessly with everything we use, allowing us to bring our most creative designs to life."

4. Optimization of Production Process Flow

The performance of No Glue Line Edge Banding Adhesive is further enhanced by optimizing the production process flow. Unlike traditional edge banding, which requires careful coordination of temperature, pressure, and post-processing, Tonren’s Seamless Edge Bonding Solution is designed to integrate seamlessly into existing production lines—with minimal adjustments—while delivering superior results. Below is a step-by-step breakdown of the optimized process flow and its key advantages.

4.1 Pre-Process Preparation: Ensuring Surface Purity

The foundation of a seamless bond is a clean, dry surface. The optimized process begins with:

Substrate Preparation: The edges of the substrate (MDF, particleboard, etc.) are sanded to a smooth finish (180-240 grit) to remove burrs, dust, and debris. This ensures maximum contact between the substrate and the adhesive.

Edge Band Preparation: The edge band is cut to the exact length of the substrate edge and pre-heated to 40-50℃ (for wood veneer edge bands) to improve flexibility and adhesion. For high-gloss edge bands, no pre-heating is required—reducing the risk of finish damage.

Adhesive Application: Tonren’s No Glue Line Edge Banding Adhesive is applied using a precision roller coater or spray system. The adhesive’s low melt viscosity allows for a thin, uniform application (0.01-0.02mm) that covers the entire edge surface without pooling or excess.

Key advantage: Unlike traditional adhesives, which require thick application to ensure bond strength, Tonren’s adhesive delivers maximum adhesion with minimal coverage—eliminating squeeze-out and glue line visibility.

4.2 Bonding Process: Precision Temperature and Pressure Control

The bonding step is critical to achieving an invisible bond. The optimized process uses:

Temperature Control: The bonding station is set to 130-150℃—low enough to protect premium finishes but high enough to activate the adhesive’s micro-encapsulation technology. The temperature is monitored in real-time using infrared sensors to ensure consistency.

Pressure Control: A hydraulic pressing system applies uniform pressure (0.8-1.2 MPa) across the entire edge surface. The pressure is maintained for 3-5 seconds—long enough for the adhesive to cure but short enough to avoid substrate warping.

Alignment Precision: Computerized vision systems ensure that the edge band is aligned perfectly with the substrate edge—within ±0.1mm tolerance. This eliminates misalignment, which can create gaps and visible lines.

Key advantage: The combination of low temperature, uniform pressure, and precise alignment ensures a seamless bond with zero squeeze-out—eliminating the need for post-processing.

4.3 Curing Process: Fast, Efficient, and Durable

Tonren’s No Glue Line Edge Banding Adhesive cures in just 3-5 seconds at bonding temperature, allowing the product to move directly to the next production step—without cooling time. For applications requiring extra durability (such as kitchen cabinets and bathroom vanities), a post-curing step is optional:

Key advantage: The fast curing time reduces production cycle time by 30-40% compared to traditional processes, increasing throughput and reducing work-in-progress inventory.

4.4 Quality Inspection: Ensuring Invisibility and Durability

The optimized process includes built-in quality inspection points to ensure every product meets Tonren’s high standards:

Visual Inspection: A team member inspects the bond line with the naked eye and a 10x magnifying glass to verify invisibility. Any products with visible lines (less than 1% of production) are rejected.

Bond Strength Testing: Random samples are tested for shear strength and peeling resistance using a universal testing machine. Only products that meet or exceed Tonren’s specifications (≥3.0 MPa shear strength) are shipped.

Yellowing Resistance Testing: Periodic samples are subjected to accelerated UV exposure tests to ensure long-term color stability.

Key advantage: The quality inspection process is streamlined and efficient—adding just 10-15 seconds per unit—while ensuring consistent, premium results.

4.5 Integration with Existing Production Lines

One of the biggest advantages of Tonren’s No Glue Line Edge Banding Adhesive is its compatibility with existing edge banding machines. Manufacturers do not need to invest in new equipment—only minor adjustments are required:

Temperature Adjustment: Reduce the bonding station temperature from 160-180℃ to 130-150℃.

Adhesive Application Adjustment: Calibrate the roller coater or spray system to apply a thinner layer of adhesive (0.01-0.02mm).

Pressure Adjustment: Optimize the pressing pressure to 0.8-1.2 MPa.

These adjustments can be made in a single day, minimizing downtime and ensuring a smooth transition. A furniture manufacturer in Vietnam reported that switching to Tonren’s adhesive required just 8 hours of equipment adjustment and no production downtime.

5. Application Scenarios and Value Manifestation

The No Glue Line Edge Banding Adhesive from Tonren Adhesive is versatile enough to meet the demands of a wide range of high-end furniture and interior design applications. Its seamless, durable, and aesthetically superior bond makes it ideal for scenarios where perfection is non-negotiable. Below are the key application scenarios and the value it delivers to manufacturers and end-users.

5.1 High-End Residential Furniture

In luxury homes, every detail matters—and edge banding is no exception. Tonren’s Invisible Edge Banding Glue is widely used in:

Kitchen Cabinets: High-gloss, matte, or wood veneer kitchen cabinets benefit from the adhesive’s invisible bond, which enhances the clean, modern look of the space. The adhesive’s moisture resistance also makes it ideal for kitchen environments, where humidity and spills are common.

Wardrobes and Closets: Custom wardrobes with mirrored, glass, or wood finishes require seamless edge banding to maintain their premium appearance. Tonren’s adhesive ensures that the edges of shelves, doors, and drawers blend seamlessly with the overall design.

Living Room Furniture: Coffee tables, sideboards, and TV stands with natural wood veneers or monochromatic finishes rely on the adhesive’s invisible bond to preserve the material’s natural beauty. The adhesive’s UV resistance also ensures that the furniture remains looking new for years.

Value Manifestation: For manufacturers, the adhesive enables them to command premium prices (15-20% higher than standard furniture) and attract discerning customers. For homeowners, it delivers furniture that is both beautiful and durable—enhancing the value of their homes.

5.2 Commercial Interior Design

Commercial spaces such as hotels, restaurants, retail stores, and offices require furniture that is not only aesthetically pleasing but also durable enough to withstand heavy use. Tonren’s No Glue Line Edge Banding Adhesive is ideal for:

Hotel Furniture: Guest room furniture, lobby desks, and restaurant tables need to maintain a pristine appearance for years. The adhesive’s durability and resistance to yellowing and peeling ensure that the furniture looks new even after thousands of guests.

Retail Store Fixtures: Shelves, display cases, and checkout counters with high-gloss or branded finishes require seamless edge banding to reinforce the store’s premium image. The adhesive’s invisible bond ensures that the focus remains on the products, not the furniture.

Office Furniture: Executive desks, conference tables, and workstation partitions benefit from the adhesive’s professional, seamless appearance. The adhesive’s durability also reduces maintenance costs for office managers.

Value Manifestation: For commercial clients, the adhesive reduces replacement costs by extending the lifespan of furniture (from 3-5 years to 8-10 years). For manufacturers, it opens up high-value commercial markets and builds long-term client relationships.

5.3 Custom Furniture and Bespoke Design

Custom furniture designers and artisans often work with unique materials and complex designs, requiring an adhesive that can adapt to their creative vision. Tonren’s Seamless Edge Bonding Solution is perfect for:

Curved Furniture: Chairs, tables, and cabinets with curved edges require an adhesive that can bond evenly without squeeze-out. Tonren’s adhesive’s uniform application and flexibility make it ideal for curved surfaces.

Reclaimed Wood Furniture: Reclaimed wood veneers and substrates have irregular surfaces and unique grain patterns. The adhesive’s ability to penetrate micro-pores and form a strong bond without altering the wood’s appearance preserves the material’s character.

Mixed-Material Furniture: Furniture that combines wood, glass, metal, and plastic requires an adhesive that can bond different materials seamlessly. Tonren’s adhesive’s broad compatibility ensures a consistent, invisible bond across all materials.

Value Manifestation: For designers, the adhesive eliminates creative constraints, allowing them to explore new shapes, materials, and finishes. For manufacturers, it enables the production of one-of-a-kind pieces that command premium prices and stand out in the market.

5.4 Healthcare and Hospitality Furniture

Furniture used in healthcare facilities (hospitals, clinics) and hospitality settings (nursing homes, assisted living facilities) requires not only aesthetics and durability but also hygiene. Tonren’s No Glue Line Edge Banding Adhesive meets these demands:

Hygiene: The seamless bond eliminates gaps where bacteria and germs can accumulate, making the furniture easier to clean and disinfect.

Durability: The adhesive’s resistance to moisture and wear ensures that the furniture can withstand frequent cleaning and heavy use.

Safety: The adhesive is low-VOC and non-toxic, meeting the strict environmental and safety standards for healthcare facilities.

Value Manifestation: For healthcare and hospitality providers, the adhesive improves hygiene and reduces the risk of infections. For manufacturers, it positions them as a trusted supplier of safe, high-quality furniture for regulated industries.

6. In-Depth Analysis of Cost-Benefits

While Tonren’s No Glue Line Edge Banding Adhesive is a premium product, its cost-benefit ratio is exceptional. Manufacturers who invest in this Glueless Edge Banding Technology often see a return on investment (ROI) within 3-6 months, thanks to savings in labor, materials, and waste—plus increased revenue from premium pricing. Below is a detailed analysis of the costs and benefits.

6.1 Initial Investment and Direct Costs

The initial cost of Tonren’s No Glue Line Edge Banding Adhesive is higher than that of traditional EVA or solvent-based adhesives. However, when considering the total cost of ownership (TCO), the adhesive is far more cost-effective:

| Cost Component | Traditional EVA Adhesive | Solvent-Based Adhesive | No Glue Line Edge Banding Adhesive |

| Adhesive Cost (per kg) | $3-5 | $5-8 | $8-10 |

| Adhesive Usage (per 100 units) | 5 kg | 4 kg | 2 kg |

| Total Adhesive Cost (per 100 units) | $15-25 | $20-32 | $16-20 |

| Labor Cost (per 100 units) | $60-80 (3-4 workers) | $40-60 (2-3 workers) | $20-30 (1-2 workers) |

| Post-Processing Cost (per 100 units) | $30-40 (scraping, sanding) | $20-30 (scraping) | $0 (no post-processing) |

| Scrap Cost (per 100 units) | $40-50 (8-10% scrap rate) | $25-35 (5-7% scrap rate) | $5-10 (1-2% scrap rate) |

| Total Direct Cost (per 100 units) | $145-195 | $105-157 | $41-60 |

As shown in the table, the total direct cost per 100 units is 60-70% lower with Tonren’s adhesive, despite its higher per-kilogram cost. This is due to:

Reduced Adhesive Usage: The adhesive’s high efficiency means less is needed to achieve a strong bond.

Lower Labor Costs: Fewer workers are required, and post-processing steps are eliminated.

Minimal Scrap: The low scrap rate reduces material waste and rework costs.

6.2 Indirect Cost Savings

Beyond direct costs, Tonren’s adhesive delivers significant indirect cost savings:

6.2.1 Warranty and Replacement Costs

Traditional edge banding adhesives often lead to warranty claims due to peeling, yellowing, and glue line issues. These claims cost manufacturers time, money, and brand reputation. Tonren’s No Glue Line Edge Banding Adhesive’s superior durability reduces warranty claims by 90% or more. For example:

A furniture manufacturer producing 10,000 units annually with a 5% warranty claim rate (traditional adhesive) spends $50,000-$100,000 annually on replacements.

With Tonren’s adhesive, the warranty claim rate drops to 0.5%, reducing replacement costs to $5,000-$10,000 annually—a savings of $45,000-$90,000.

6.2.2 Inventory and Storage Costs

Traditional adhesives require careful storage to prevent degradation (e.g., EVA adhesives must be stored in dry, cool environments). Tonren’s No Glue Line Edge Banding Adhesive has a longer shelf life (12 months vs. 6-8 months for traditional adhesives) and is more stable, reducing inventory waste and storage costs. Additionally, the adhesive’s compatibility with multiple substrates and edge bands means manufacturers can reduce the number of adhesive types they stock—simplifying inventory management.

6.2.3 Equipment Maintenance Costs

Traditional edge banding processes require frequent equipment maintenance due to glue buildup on rollers, scrapers, and pressing plates. Tonren’s adhesive’s low squeeze-out means less glue buildup, reducing maintenance frequency by 50%. For example, a manufacturer that spends $10,000 annually on equipment maintenance with traditional adhesives would save $5,000 annually with Tonren’s adhesive.

6.3 Revenue Growth and Premium Pricing

The most significant benefit of Tonren’s No Glue Line Edge Banding Adhesive is its ability to enable premium pricing. High-end furniture manufacturers using the adhesive can charge 15-20% more for their products, as the seamless invisible bond is a highly valued feature for discerning customers. For example:

A standard kitchen cabinet set priced at $5,000 with traditional edge banding can be priced at $5,750-$6,000 with Tonren’s adhesive—a 15-20% premium.

For a manufacturer selling 1,000 cabinet sets annually, this translates to additional revenue of $750,000-$1,000,000.

Additionally, the adhesive helps manufacturers attract new customers and expand into high-value markets (such as luxury residential, commercial, and healthcare), further boosting revenue.

6.4 ROI Calculation

To illustrate the ROI of Tonren’s No Glue Line Edge Banding Adhesive, let’s consider a medium-sized furniture manufacturer producing 50,000 units annually:

Annual Direct Cost Savings: ($145 - $41) per 100 units × 500 = $52,000 (using traditional EVA adhesive as a benchmark).

Annual Indirect Cost Savings: $45,000 (warranty) + $5,000 (inventory) + $5,000 (maintenance) = $55,000.

Annual Additional Revenue: $500 (premium per unit) × 50,000 units = $25,000,000.

Total Annual Benefit: $52,000 + $55,000 + $25,000,000 = $25,107,000.

Initial Investment: $10,000 (equipment adjustments) + $50,000 (initial adhesive stock) = $60,000.

ROI: ($25,107,000 / $60,000) × 100% = 41,845%.

Payback Period: $60,000 / ($25,107,000 / 12) ≈ 0.029 months (less than 1 day).

While this is an extreme example (largely due to the significant premium pricing), even smaller manufacturers with lower production volumes see impressive ROI. A small manufacturer producing 10,000 units annually would still achieve a payback period of less than 1 month, with annual benefits of over $5,000,000.

7. Outlook on Future Technology Trends

The high-end furniture industry is constantly evolving, with trends toward sustainability, customization, and smart design driving innovation. Tonren’s No Glue Line Edge Banding Adhesive is at the forefront of these trends, and the company’s R&D team is already working on the next generation of Glueless Edge Banding Technology. Below are the key future trends that will shape the development of invisible edge banding adhesives.

7.1 Sustainable and Eco-Friendly Formulations

As global demand for sustainable products grows, future edge banding adhesives will focus on eco-friendliness without compromising performance. Tonren is developing a bio-based No Glue Line Edge Banding Adhesive made from renewable resources (such as plant oils and natural resins). This bio-based adhesive will:

Be 100% biodegradable and compostable at the end of its lifespan.

Have zero VOC emissions, meeting the strictest environmental standards (such as EU REACH and US EPA).

Use renewable raw materials, reducing reliance on fossil fuels.

The company plans to launch this bio-based adhesive in 2027, targeting manufacturers looking to enhance their sustainability credentials and meet the demands of eco-conscious consumers.

7.2 Smart Adhesives with Self-Healing Properties

Future edge banding adhesives will incorporate smart technology to address minor damage and extend product lifespan. Tonren is researching self-healing polymers that can repair small cracks or gaps in the bond line when exposed to heat or pressure. For example:

If the edge band is slightly damaged (e.g., a small scratch or peel), applying gentle heat (such as from a hair dryer) would activate the self-healing polymer, repairing the bond and restoring the seamless appearance.

This technology would reduce maintenance costs and extend the lifespan of furniture, further enhancing its sustainability.

7.3 Enhanced Compatibility with Emerging Materials

As furniture manufacturers adopt new materials (such as carbon fiber, recycled plastics, and 3D-printed components), edge banding adhesives must evolve to bond with these materials. Tonren’s R&D team is working to expand the compatibility of its No Glue Line Edge Banding Adhesive to include:

Lightweight composites (used in modern, minimalist furniture).

Recycled and upcycled materials (aligning with circular economy trends).

3D-printed edge bands (enabling highly customized designs).

This enhanced compatibility will enable manufacturers to stay ahead of design trends and offer innovative products that stand out in the market.

7.4 Digital Integration and Precision Application

The future of edge banding will be digital, with adhesives integrated into smart production systems. Tonren is developing a digital No Glue Line Edge Banding Adhesive that can be applied using 3D printing technology. This will allow for:

Precision application of adhesive only where it is needed, even for complex, irregular edges.

Real-time monitoring of adhesive application via IoT sensors, ensuring uniform coverage and bond strength.

Integration with CAD/CAM software, enabling seamless integration of edge banding into the design process.

This digital integration will further reduce waste, improve process efficiency, and enable unprecedented design flexibility.

7.5 Global Standardization of Invisible Edge Banding

As invisible edge banding becomes the industry standard for high-end furniture, global standards will emerge to define quality and performance. Tonren is actively participating in the development of these standards (through organizations such as the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI)). The standards will cover:

Glue line visibility (maximum allowable thickness).

Bond strength and durability.

Environmental and safety requirements.

Global standardization will benefit manufacturers by providing clear quality benchmarks and simplifying compliance with international regulations.

8. Industry Standards and Certification Systems

The quality and performance of No Glue Line Edge Banding Adhesive are validated by a range of industry standards and certifications. These certifications not only confirm the adhesive’s technical superiority but also provide manufacturers with the credibility needed to enter high-value markets. Below are the key standards and certifications that apply to Tonren’s Invisible Edge Banding Glue.

8.1 Quality Management System Certifications

Tonren’s production process is certified to ISO9001:2015, the global standard for quality management systems. This certification ensures that the company’s adhesive is produced consistently to high quality standards, with strict quality control and continuous improvement. For manufacturers, this means they can rely on Tonren’s adhesive to deliver consistent results—batch after batch.

8.2 Environmental and Safety Certifications

In today’s eco-conscious market, environmental and safety certifications are critical. Tonren’s No Glue Line Edge Banding Adhesive holds the following certifications:

EU REACH Compliance: The adhesive contains no restricted substances (such as heavy metals, formaldehyde, or harmful solvents), making it eligible for sale in the European Union.

US EPA Safer Choice Certification: The adhesive meets the EPA’s strict standards for low VOC emissions and environmental safety, making it suitable for use in residential and commercial spaces.

China Environmental Label (Ten-Ring Label): China’s top environmental certification, awarded to products that meet high standards for pollution control and resource conservation.

These certifications enable manufacturers to market their furniture as environmentally friendly and safe, appealing to eco-conscious consumers and complying with global regulations.

8.3 Performance Standards

Tonren’s No Glue Line Edge Banding Adhesive meets or exceeds the following performance standards:

ISO 10933: Specifies the test methods for wood adhesives, including bond strength, water resistance, and heat resistance. Tonren’s adhesive exceeds the minimum requirements for shear strength (≥3.0 MPa) and water resistance (no bond loss after 24 hours of water immersion).

ASTM D903: Standard test method for peel strength of adhesive bonds. Tonren’s adhesive achieves a peel strength of ≥2.5 N/mm, exceeding the standard requirement of ≥1.5 N/mm.

EN 302-1: European standard for wood adhesives—requirements for structural use. Tonren’s adhesive meets the requirements for structural edge banding, ensuring long-term durability.

These performance standards confirm that Tonren’s adhesive delivers not only aesthetic superiority but also structural integrity—critical for high-end furniture.

8.4 Industry-Specific Certifications

For specialized applications, Tonren’s adhesive holds industry-specific certifications:

Healthcare Certification (ISO 13485): For use in healthcare furniture, the adhesive meets the strict quality management requirements for medical devices and healthcare products.

Marine Certification (ASTM D4023): For use in marine furniture (such as yachts and boats), the adhesive meets the requirements for saltwater resistance and durability.

Fire Safety Certification (UL 94): The adhesive has a UL 94 V-0 flammability rating, making it suitable for use in commercial spaces with strict fire safety requirements.

These industry-specific certifications open up new markets for manufacturers and demonstrate the adhesive’s versatility and reliability.

FAQ (Frequently Asked Questions)

Q1: How is No Glue Line Edge Banding Adhesive different from traditional edge banding adhesives?

A1: Unlike traditional EVA or solvent-based adhesives, No Glue Line Edge Banding Adhesive uses a proprietary polymer blend and micro-encapsulation technology to create a chemical fusion between the substrate and edge band. This results in an invisible bond line (≤0.02mm), zero yellowing, no dust accumulation, and superior durability. It also eliminates post-processing steps (scraping, sanding) and reduces labor and waste costs. Traditional adhesives rely on physical bonding, leading to visible glue lines, yellowing, and premature peeling.

Q2: Can No Glue Line Edge Banding Adhesive be used with existing edge banding machines?

A2: Yes! The adhesive is designed to integrate seamlessly into existing production lines with minimal adjustments. You only need to optimize three parameters: reduce the bonding temperature to 130-150℃, adjust the adhesive application to a thin layer (0.01-0.02mm), and set the pressing pressure to 0.8-1.2 MPa. These adjustments can be made in a single day, with no need for new equipment.

Q3: Is the adhesive compatible with all types of substrates and edge bands?

A3: Absolutely. The adhesive is engineered to bond seamlessly with all common substrates (MDF, particleboard, plywood, solid wood, low-formaldehyde boards) and edge bands (PVC, ABS, acrylic, wood veneer, melamine, high-gloss finishes). It also works with specialized materials such as reclaimed wood, curved edges, and thin edge bands (≤0.5mm). Tonren’s R&D team can also customize the adhesive for unique materials upon request.

Q4: How long does the adhesive last, and does it yellow over time?

A4: The adhesive delivers exceptional durability, with a bond life of 8+ years—even in humid or high-UV environments. It contains UV stabilizers and antioxidants that prevent yellowing, and accelerated aging tests show no discoloration after 5+ years of use. This is far superior to traditional EVA adhesives, which yellow in 6-12 months, and solvent-based adhesives, which yellow in 12-24 months.

Q5: Is the adhesive environmentally friendly and safe?

A5: Yes. The adhesive is low-VOC, non-toxic, and fully compliant with global environmental standards (EU REACH, US EPA Safer Choice, China Ten-Ring Label). It contains no harmful solvents, heavy metals, or formaldehyde, making it safe for use in residential, commercial, and healthcare spaces. Tonren is also developing a bio-based version of the adhesive (launching in 2027) that is 100% biodegradable.

Q6: What is the ROI for switching to No Glue Line Edge Banding Adhesive?

A6: Most manufacturers achieve ROI within 3-6 months, thanks to significant cost savings (labor, materials, waste) and increased revenue from premium pricing. For example, a medium-sized manufacturer producing 50,000 units annually can save $107,000 in direct and indirect costs and generate an additional $25,000,000 in revenue from premium pricing—resulting in an ROI of over 40,000% and a payback period of less than 1 day. Even smaller manufacturers see impressive ROI, with payback periods of 1-3 months.

Call to Action

In the high-end furniture market, perfection is not an option—it’s a requirement. The visible glue lines, yellowing, and peeling of traditional edge banding processes are no longer acceptable to discerning customers who demand seamless, durable, and beautiful furniture. Tonren’s No Glue Line Edge Banding Adhesive—backed by 26 years of expertise and ISO9001 certification—delivers the "seamless invisible" craftsmanship that redefines premium edge banding.

Whether you’re a furniture manufacturer looking to command higher prices, a custom designer seeking to push creative boundaries, or a commercial client needing durable, hygienic furniture, Tonren’s Invisible Edge Banding Glue is the solution you’ve been waiting for. With its superior aesthetics, durability, and cost-benefit ratio, it’s the key to standing out in a competitive market and building a reputation for quality.

Don’t let traditional adhesives hold you back. Contact Foshan Tonren Adhesive Co., Ltd. today to request a sample, schedule a demo, or learn more about how No Glue Line Edge Banding Adhesive can transform your products. Visit our website at [insert website] or email us at [insert email] to start your journey toward seamless, invisible perfection.

Summary

The pursuit of "seamless invisible" craftsmanship in high-end furniture has long been hindered by the limitations of traditional edge banding adhesives. But with Tonren’s No Glue Line Edge Banding Adhesive, that pursuit is now a reality. This revolutionary Seamless Edge Bonding Solution—built on advanced polymer chemistry, micro-encapsulation technology, and precision formulation—eliminates visible glue lines, yellowing, dust accumulation, and peeling, delivering a bond that is as durable as it is aesthetically superior.

From high-end residential furniture to commercial interiors, custom designs to healthcare settings, Tonren’s adhesive adapts to a wide range of applications, enabling manufacturers to meet the demands of discerning customers and expand into high-value markets. Its exceptional cost-benefit ratio—driven by labor and material savings, minimal waste, and premium pricing—ensures a rapid ROI, making it a smart investment for businesses of all sizes.

As the industry trends toward sustainability, customization, and digital integration, Tonren remains at the forefront of innovation, developing bio-based formulations, self-healing technology, and digital integration to shape the future of invisible edge banding. Backed by rigorous quality control, global certifications, and a commitment to excellence, Tonren’s No Glue Line Edge Banding Adhesive is not just a product—it’s a game-changer that redefines the quality standards for high-end furniture.

The future of edge banding is invisible. Are you ready to join the revolution?